Hydraulic pipes have been around for centuries and are used in various industries, from construction and farming to aviation and transportation. But what exactly are hydraulic pipes, and how do they work? This blog post dwells on the basics of hydraulic pipes, including their composition, purpose, and function.

What are Hydraulic Pipes?

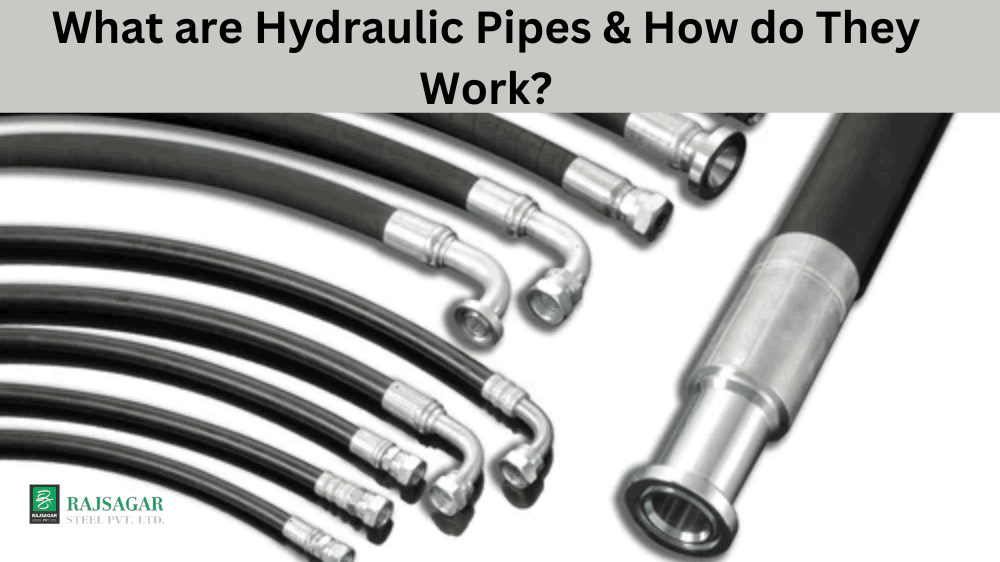

Hydraulic pipes are flexible piping that uses hydraulic pressure to carry fluids. They are typically made of metal or polymers, depending on the application and working environment they will be exposed to. Hydraulic pipes allow for leakage-proof connections at high-pressure ratings and can be used for multiple applications such as pumps, valves, machines, etc. Hydraulic pipes use for precise control and movement without exerting too much force or energy due to their ability to effectively transfer the pressurized fluid. Additionally, this pipe prevents the loss of liquid from an area where air would otherwise create its hydraulic motor force, which could damage machinery or systems within the piping network. In summary, Hydraulic Pipes are flexible tubing used in many industrial settings with the capability to withstand influence from various pressures and temperatures while providing reliable fluid transmission capabilities throughout its network.

The Ins and Outs of Hydraulic Pipes: Understanding How They Work

Firstly, let’s learn what hydraulic pipes are. Hydraulic pipes, or hydraulic hoses, are flexible tubes made of high-pressure material that transmit energy and hydraulic fluid between hydraulic components. These components could be anything from a pump to a cylinder or a motor. The hydraulic fluid is usually oil or water-based and is used to generate power to operate machinery and equipment.

Hydraulic pipes are made of several layers of materials to ensure maximum durability and flexibility. The innermost layer is made of a thermoplastic or rubber material that can withstand high pressures and fluid rigours. The outer layer is a protective material to prevent environmental damage, such as abrasion or UV radiation. In between these layers are wire or textile reinforcements that support the pipe.

The function of hydraulic pipes is to transmit the hydraulic fluid from one component to another, generating power along the way. The hydraulic fluid is pumped from a reservoir or tank, fed through a pump, and sent into a hydraulic system. The fluid powers the components of the system by creating pressure, which forces the mechanical parts to move. The hydraulic fluid is then returned to the reservoir to start the cycle.

Hydraulic pipes are used in various applications across different industries. In the construction and farming industries, hydraulic pipes power machinery such as bulldozers, backhoes, and harvesters. In aviation, hydraulic pipes operate landing gear and control surfaces. Hydraulic pipes are used to power brakes, steering, and suspension systems in transportation. Hydraulic pipes require regular maintenance to ensure maximum efficiency and safety despite their durability. This includes inspecting the pipes for any signs of wear or damage and replacing them as necessary. Maintaining the proper fluid levels and pressure in the hydraulic system is important.

Conclusion:

In conclusion, hydraulic pipes are essential to many industries, serving as the backbone of countless machinery and equipment. Understanding the basics of hydraulic pipes and how they work can help us appreciate their vital role in our daily lives. As with any machinery, regular maintenance and care ensure that hydraulic pipes function effectively and safely.