Carbon Steel IS 3589 FE 330 Pipes Specifications

Dimensions : ASTM, ASME and API

Diameter : 168.3 MM TO 406.4 MM / 6 TO 16

(INCH)

Length : in any length from 4 m to 12 m as per

customer choice

Type : ERW

End : Plain End, Beveled End, Treaded

Schedules : SCH 40, SCH 80, SCH 160, SCH XS, SCH

XXS, All Schedules

Strength tests

- Leakage test

- Mechanical test

- Compression test

- Hardness test

- Tensile test

- Thermal property analysis

Material tests-

- Micro test

- Chemical analysis

- Macro test

- Pitting corrosion test

- PMI test

- Radiography

MS IS 3589 ERW Pipes Confirming to IS 3589, Grade FE 330

| NB | NB | 0D | Light | Medium | Heavy | |||

| Thick | Weight | Thick | Weight | Thick | Weight | |||

| MM | IN | MM | MM | Kg/mtr. | MM | Kg/mtr. | MM | Kg/mtr. |

| 6mm | 1/8" | 10.32 | 1.80 | 0.361 | 2.00 | 0.407 | 2.65 | 0.493 |

| 8mm | 1/4" | 13.49 | 1.80 | 0.517 | 2.35 | 0.650 | 2.90 | 0.769 |

| 10mm | 3/8" | 17.10 | 1.80 | 0.674 | 2.35 | 0.852 | 2.90 | 1.020 |

| 15mm | 1/2" | 21.43 | 2.00 | 0.952 | 2.65 | 1.122 | 3.25 | 1.450 |

| 20mm | 3/4" | 27.20 | 2.35 | 1.410 | 2.65 | 1.580 | 3.25 | 1.900 |

| 25mm | 1" | 33.80 | 2.65 | 2.010 | 3.25 | 2.440 | 4.05 | 2.970 |

| 32mm | 11/4" | 42.90 | 2.65 | 2.580 | 3.25 | 3.140 | 4.05 | 3.840 |

| 40mm | 11/2" | 48.40 | 2.90 | 3.250 | 3.25 | 3.610 | 4.05 | 4.430 |

| 50mm | 2" | 60.30 | 2.90 | 4.110 | 3.65 | 5.100 | 4.47 | 6.170 |

| 65mm | 21/2' | 76.20 | 3.25 | 5.840 | 3.65 | 6.610 | 4.47 | 7.900 |

| 80mm | 3" | 88.90 | 3.25 | 6.810 | 4.05 | 8.470 | 4.85 | 10.100 |

| 100mm | 4" | 114.30 | 3.65 | 9.890 | 4.50 | 12.100 | 5.40 | 14.400 |

| 125mm | 5" | 139.70 | ..... | ...... | 4.85 | 16.200 | 5.40 | 17.800 |

| 150mm | 6" | 165.10 | ...... | ....... | 4.85 | 19.200 | 5.40 | 21.200 |

| BIG DIAMETER ERW PIPES(CONFIRM TO IS 3589) | ||||||||

|

WallThick. mm |

7"NB 193.7 Kg/mtr |

8"NB 219.1 Kg/mtr |

10"NB 273 Kg/mtr |

12"NB 323.7 Kg/mtr |

14"NB 355.6 Kg/mtr |

16"NB 406.4 Kg/mtr |

18"NB 454 Kg/mtr |

20"NB 508 Kg/mtr |

| 4.85 | 22.59 | 25.62 | 32.07 | 38.13 | ...... | ........ | ....... | ....... |

| 5.20 | 24.17 | 27.43 | 34.34 | 40.84 | ...... | ........ | ........ | ........ |

| 5.60 | 26.00 | 29.28 | 36.93 | 43.93 | 48.11 | ........ | ......... | .......... |

| 6.00 | 27.88 | 31.53 | 39.50 | 47.02 | 51.49 | 61.00 | 69.00 | ........ |

| 6.35 | 29.34 | 33.28 | 41.73 | 49.67 | 54.43 | 62.35 | 70.50 | 78.50 |

| 7.01 | 32.27 | 36.76 | 46.43 | 55.45 | 61.82 | 69.04 | ...... | ...... |

| 7.94 | ..... | 41.00 | 50.95 | 61.85 | 67.98 | 77.92 | 87.80 | ....... |

| 8.18 | ...... | 42.56 | 53.42 | 65.12 | ...... | ...... | ...... | ...... |

| 9.53 | ...... | 51.50 | 60.24 | 73.75 | 81.21 | 93.13 | 105.00 | 117.00 |

| 12.70 | ...... | ..... | ...... | ...... | 107.28 | 123.30 | 139.00 | 155.00 |

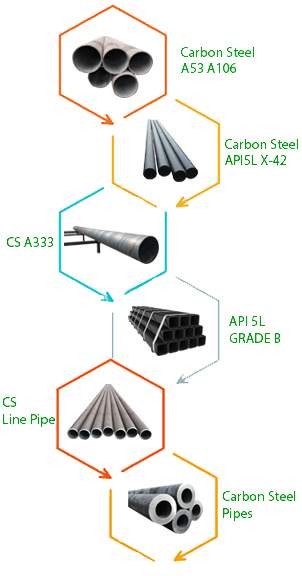

| Other Types of IS 3589 FE 330 Pipes |

|---|

|

IS 3589 FE 330 Pipes Application

Carbon Steel IS 3589 FE 330 Pipes are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of IS 3589 FE 330 Pipe through a worldwide network of stock-keeping branches. These IS 3589 Pipes is use in various industries like :

- IS 3589 FE 330 Pipes uses in Oil and Gas Pipeline

- IS 3589 Steel Pipes uses in Chemical Industry

- IS 3589 FE 330 Pipes uses in Plumbing

- IS 3589 FE 330 Mild Steel Pipes uses in Heating

- IS 3589 Black ERW Pipe uses in Water Supply Systems

- Carbon Steel IS 3589 Pipe uses in Power Plant

- Carbon Steel IS 3589 FE 330 ERW Pipes uses in Paper & Pulp Industry

- IS 3589 Black ERW Pipe uses in General Purpose Applications

- IS 3589 FE 330 Pipe uses in Fabrication Industry

Cities We Supply

| Carbon Steel IS 3589 Pipes Manufacturer in Surat | IS 3589 Steel Pipes Stockholder in Surendranagar |

| CS IS 3589 FE 330 Pipes Supplier in Dahod | Carbon Steel IS 3589 Pipes Stockist in Gandhinagar |

| IS3589 FE 330 Mild Steel Pipes stockist in Rajkot | High Quality CS IS3589 FE 330 Pipes Exporter in Sabarkantha |

| CS IS3589 FE 330 ERW Pipes Supplier in Kheda | IS 3589 FE 330 Pipes Distributor in Kutch |

| CS IS 3589 FE 330 Pipes Supplier in Jamnagar | IS 3589 FE 330 Pipes Supplier in Junagadh |

| IS 3589 FE 330 Galvanized CS Pipes Stockholder in Mehsana | IS 3589 Mild Steel Pipes Supplier in Narmada |

| IS 3589 FE 330 Pipes Dealer in Patan | IS 3589 Black ERW Pipes Stockholder in Porbandar |

| MS IS 3589 Pipes Supplier in Anand | IS 3589 Pipes Stockist in Banaskantha |

| Top Quality Carbon Steel IS 3589 Pipes Supplier in Ahmedabad | IS 3589 FE 330 ERW Pipes Dealer in Amreli |

| IS 3589 Pipe Distributor in Bharuch | IS 3589 MS Pipe Weight Chart Manufacturer in Bhavnagar |

| IS 3589 FE 330 Pipes Supplier in Navsari | CS IS 3589 FE 330 Pipes Manufacturer in Panchmahal |

| High Quality CS IS3589 FE 330 Pipes Stockist in Vadodara | CS IS3589 FE 330 ERW Pipes in Valsad |

Suppliers and Stockists of IS 3589 FE 330 Pipes in Cities Like

|

Ahmedabad |

Gandhinagar |

Surat |

Rajkot |

Jindal IS 3589 FE 330 Pipes Stockholder in Rajkot, IS 3589 FE 330 Galvanized Carbon Steel Pipes in Vadodara, IS 3589 FE 330 Mild Steel Pipes, Mild Steel IS 3589 FE 330 Black ERW Pipes, IS 3589 FE 330 ERW Pipes Distributor in Ankleshwar, IS 3589 Pipe Dealer in Surat.

Grade 330-

Grade 330 is a high alloy stainless steel. Quantity of chromium is in the range of 4- 30% so this alloy has high corrosion resistance. Grade 330 is of high strength and resistance. This grade has resistance to carburization and oxidation at 1200 degree Celsius. This grade easily performance in hot working, but its working is difficult to cold working. This is grade 330 stainless steel is unresponsive to heat treatment.

Technical manufacturing-

We modify our product to improve the quality of all level of pipes. We try to improve our pipe by physical and technical approach. Normal pipe size is the standard sizes of pipes used in high and low pressure and temperatures. Pipe size is based on two non-dimensional numbers; a nominal pipe size and schedule pipe size.

IPS system is established to designate the pipe size. Approximate inside diameter is based on size representation in the form of inches. Users mostly used the size of pipes as 2 inches, 4 inches, 6 inches and so on and their outside diameter of the pipe is standardized. The pipe thickness is set and increasing wall thickness of the pipe increases the strength of the pipe.

Quality-

Quality of product improves our business in the market. Quality plays a most important role in the business. Our company provides a department who works on the quality of the material. They believe in quality, qualified engineering and quality of the product. Our department maintains the highest level of quality of the product by performing various tests. Our company provides guarantees for their product, responsible service, and on-time delivery.

Product feature-

Some of the greatest features offered by this IS 3589 Carbon Steel Grade 330 Pipes are as follows-

• Corrosion resistance

• Accurate dimension

• Rustproof finish

• Ensure excellence stress distribution

• Sustained with high presser and temperature

Testing-

Testing is necessary it clear all doubt and finally pipes get ready for all applications. Various tests are performed in order to detect defects in the product and to test its quality. Our company also does many tests like

• Chemical examination test

• Fitting protection test

• Hydrostatic test

• Impact analysis test

• Hardness test

• Pitting corrosion test

Packaging-

The packaging is most important because during delivery our pipes are vulnerable to damage. Our company focuses when we pack our pipes and pack our Carbon Steel IS 3589 FE 330 Pipes in multiple ways such as

• Cartoon box

• Wooden boxes

• Wooden crates

• Shrink-wrapped

Different applications need these types of pipes which work long time. Our product will for sure last long in your application.