Carbon Steel API 5L Seamless Pipe Specifications

Standard : API 5L

Sizes : 16'OD TO 54' OD (8 MM TO 50 MM THK)

Outer Diameter : 219.1mm – 4064mm (8" – 160")

Wall Thickness : 3.2 mm – 40mm (SCH5, SCH10, SCH20,

SCh20, STD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160,

XXS)

Lengths :Single Random, Double Random or as per

Custom Requirement

Surface Finishes :FBE, FBE Dual, 3LPE, 3LPP, Coal

Tar, Bare, Oiled, Mill Varnish, Galv, Concrete Coating and Tape

Wrap, single-layer/double-layer FBE, 2PE, 3PE,3PP and other

anti-corrosion coatings with the performed standards such as

DIN30670, DIN30671,DIN30678,CAN/CSA-Z245.21-M92,SY/T4013-2002 and

SY/T0315-97 etc.

End Finishes :Beveled, Square Cut, Threaded &

Coupled.

Strength tests-

- Leakage test

- Mechanical test

- Compression test

- Hardness test

- Tensile test

- Thermal property analysis

Material tests-

- Micro test

- Chemical analysis

- Macro test

- Pitting corrosion test

- PMI test

- Radiography

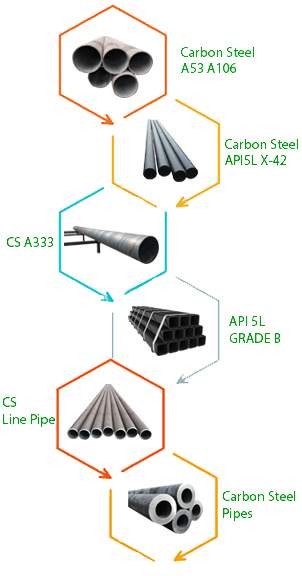

| Other Types of Carbon Steel API 5L Seamless Pipe |

|---|

|

API 5L Seamless Pipes Application

Carbon Steel API 5L Seamless Pipe are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of CS API 5L X80 PSL 1/2 Pipes through a worldwide network of stock-keeping branches. These CS API 5L Seamless Pipes is use in various industries like :

- Carbon Steel API 5L Seamless Pipe uses in Oil and Gas Pipeline

- API 5L Seamless Pipes uses in Chemical Industry

- Carbon Steel Seamless Pipes uses in Plumbing

- CS Seamless Pipe Line Pipes uses in Heating

- API 5L PSL1 CS Seamless Pipes uses in Water Supply Systems

- API 5L Carbon Steel Seamless Pipes uses in Power Plant

- Seamless Pipes uses in Paper & Pulp Industry

- API 5L Seamless Line Pipe uses in General Purpose Applications

- Seamless Carbon Steel Pipes uses in Fabrication Industry

Cities We Supply

| Carbon Steel Seamless Pipes Stockist in Dahod | CS Seamless Pipe Supplier in Gandhinagar |

| Carbon Steel PSL 1 Seamless Pipes in Jamnagar | Seamless Steel Pipes Stockholder in Junagadh |

| Thick Walled Large Diameter Seamless Pipe Supplier in Vadodara | API 5l Seamless Line Pipe Dealer in Valsad |

| API 5L X70 PSL 1 Seamless Pipe Supplier in Anand | API 5L Seamless Pipe in Banaskantha |

| carbon steel API 5L GR.B Seamless Pipe Dealer in Rajkot | API 5L Seamless Line Pipe Stockist in Sabarkantha |

| API 5L X80 Seamless Pipes Supplier in Ahmedabad | Top Quality Seamless Line Pipe Dealer in Amreli |

| API 5L X70 PSL 2 Seamless Pipe Supplier in Kheda | Carbon Steel Seamless Pipes Manufacturer in Kutch |

| PSL 2 Seamless Pipe Dealer in Bharuch | CS API 5L Seamless Pipe Supplier in Bhavnagar |

| Carbon Steel API 5L Seamless Pipes in Mehsana | API 5L Seamless PSL 1/2 Pipe Dealer in Narmada |

| Carbon Steel Seamless PSL 1/2 Pipes Supplier in Navsari | API 5L L320 or X46 PSL1 Seamless Pipes Manufacturer in Panchmahal |

| High yield API 5L Seamless Pipe Stockist in Surat | Carbon Steel Seamless Pipes in Surendranagar |

| API 5L Seamless Pipes in Patan | API 5L Carbon Steel Seamless Pipes Manufacturer in Porbandar |

Suppliers and Stockists of API 5L Seamless Pipe in Cities Like

|

Ahmedabad |

Gandhinagar |

Surat |

Rajkot |

API 5L PSL2 Seamless Line Pipe Dealer in Ankleshwar, API 5L CS Seamless Pipes Supplier in Ankleshwar, API 5L PSL1 Carbon Steel Seamless Pipes Stockist in Surat, API 5L X-Series Seamless Pipe, API 5L Seamless Pipe, API 5L PSL1 Seamless Steel Pipe Stockist in Baroda.

Quality assurance and testing of the pipes manufactured:

Quality of the API 5L Seamless Pipe is maintained by the organization. The main aim of the company is to provide the customers with the best quality of pipes which fulfills their expectations. All the manufacturing norms are strictly followed at the time manufacturing of the seamless pipes. The appropriate ranges are set according to the provided national and international quality standards. Other than the quality checks the quality controllers conduct different tests. They conduct these tests to assure the clients about the product that is delivered to them. Some tests that are performed are-

Furthermore, the organizations conduct many inspections regarding the quality of the pipes that are manufactured by the workers. For the final assurance of the pipe’s quality the inspections are conducted. These are conducted by the world’s reputed third-party inspection squad. They have good knowledge about the manufacturing guidelines of the pipes.

Documents involved

many documents are involved in the delivery of the pipes. The documents are attached to the pipes that are delivered to ensure the clients that no harmful or poor quality of the material is used in the production of the pipes. Documents that are attached are-

Packaging of the Pipes-

The API 5L Seamless Pipe is packed with the plastic cover to protect the pipe from the extreme weather conditions. The plastic packed pipes are then packed in the wooden boxes, pallets, and the crates which are done to avoid rust during the process of delivery of the pipes. All the essential marks are attached to the wooden boxes along with the proper product details. The product details contain the product size, shape, heat number, etc.