Carbon Steel LSAW Pipe Specifications

Standard : ASTM A53, A106, API 5L, ASME

B36.10M-1996, DIN1626, DIN1629, DIN17175, DIN 2448, JIS G3452, JIS

G3454, JIS G3455, JIS G3456, JIS G3457, JIS G3461

Dimensions : ASTM, ASME and API

Size (LSAW) :

Outer Diameter : 219mm-1820mm

Wall Thickness : 5.0mm-50mm

Schedule : SCH 40, SCH 80, SCH 160, SCH XS, SCH

XXS, All Schedules

Packing : In bundles, Anticorrosion heat

preservation, Varnish coating, Ends can be bevelled or square cut,

End Capped Certification & supplementary test, Finishing &

Identity Mark

Surface Protection : Black (Self Coloured

uncoated), Varnish/Oil Coating, Pre-Galvanized, Hot Dip Galvanized

End : Plain End, Beveled End, Screwed, Treaded

Length : 6mtr-18mtr -Single Random, Double Random

& Required Length, Custom Size

Strength tests

- Leakage test

- Mechanical test

- Compression test

- Hardness test

- Tensile test

- Thermal property analysis

Material tests-

- Micro test

- Chemical analysis

- Macro test

- Pitting corrosion test

- PMI test

- Radiography

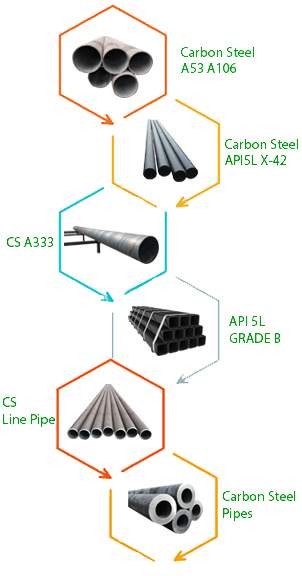

Available Specification

| Sr No | DESCRIPTION | GRADE | SIZE RANGE |

| 1 | Carbon Steel LSAW Pipes | A53 / A106 / API 5L Grade B (NACE – MR -0175) |

1/2″ – 24″ |

| 2 | Carbon Steel LSAW Black Steel Pipes | A53 Grade A – B / API 5L – A53, Grade B( NACE MR-0175) | 1/2″ – 16″ |

| 3 | Carbon Steel LSAW Pipes | API 5L / ASTM A671/ 672 ( up to Grade X-70) | 12″ – 135 “ |

| Other Types of Carbon Steel LSAW Pipes |

|---|

|

Carbon Steel LSAW Pipe Application

Carbon Steel LSAW Pipe are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of Carbon Steel LSAW Pipe through a worldwide network of stock-keeping branches. These Carbon Steel LSAW Pipes is use in various industries like :

- Carbon Steel LSAW Pipe uses in Oil and Gas Pipeline

- Carbon Steel LSAW Pipe uses in Chemical Industry

- Carbon Steel LSAW Pipe uses in Plumbing

- CS ASME SA53 Grade B LSAW Pipe uses in Heating

- ASME SA106 Gr B Carbon Steel LSAW Pipe uses in Water Supply Systems

- Carbon Steel LSAW Pipe Pipe uses in Power Plant

- Carbon Steel LSAW Pipe uses in Paper & Pulp Industry

- Carbon Steel LSAW Pipe uses in General Purpose Applications

- Carbon Steel LSAW Pipe uses in Fabrication Industry

Cities We Supply

| Carbon Steel High Yield LSAW Pipes Manufacturer in Surat | ASTM A53 Carbon Steel LSAW Pipes Stockholder in Surendranagar |

| ASTM A106 Carbon Steel LSAW Pipes Supplier in Dahod | Carbon Steel LSAW Pipes Stockist in Gandhinagar |

| ASTM S/A 53 Steel LSAW Pipes Stockholder in Mehsana | ASTM S/A 106 Steel LSAW Pipes Supplier in Narmada |

| Carbon Steel LSAW Pipes Dealer in Patan | Carbon Steel Longitudinally Submerged Arc Welded Steel pipes Stockholder in Porbandar |

| Carbon Steel LSAW Pipes Supplier in Anand | Carbon Steel LSAW Pipes Stockist in Banaskantha |

| Carbon Steel Schedule 40 LSAW pipes stockist in Rajkot | Carbon Steel LSAW Pipes Supplier in Sabarkantha |

| LSAW Carbon Steel Schedule 80 Pipes Supplier in Kheda | CS LSAW Pipes Distributor in Kutch |

| Black and Galvanized Steel LSAW Pipes Supplier in Jamnagar | Carbon LSAW Pipes Supplier in Junagadh |

| CS LSAW Welded Sprial Steel Pipes Supplier in Ahmedabad | Large Diameter Carbon Steel LSAW Pipes Dealer in Amreli |

| Carbon Steel LSAW Pipes Distributor in Bharuch | Top Quality Carbon Steel LSAW Pipes Manufacturer in Bhavnagar |

| Carbon Steel Jindal LSAW pipes Supplier in Navsari | LSAW steel pipes Manufacturer in Panchmahal |

| Carbon Steel LSAW Pipe Size Stockist in Vadodara | Carbon Steel LSAW Pipes in Valsad |

Suppliers and Stockists of Carbon Steel LSAW Pipes in Cities Like

|

Ahmedabad |

Gandhinagar |

Surat |

Rajkot |

High Yield Carbon Steel LSAW Pipe Distributor in Ankleshwar, CS LSAW Pipes Stockholder in Surat, Carbon Steel LSAW Pipes in Vadodara, Carbon Steel LSAW Line Pipe, Carbon Steel LSAW Pipe Dealer in Rajkot.

The quality of the pipes that we manufacture are stringently checked at the appropriate step of the manufacturing process. The manufacturing process of the Carbon Steel Lsaw Pipe is done under the strict supervision of the hired professional experts. They have excellent knowledge about the development of the pipes. All the manufacturing norms are followed by the quality checkers to produce superior quality of pipes. While setting the ranges of the pipes all the national and international quality standards are properly studied.

The quality controllers ensure the clients about the quality of the pipes which are delivered to them. Also, the pipes are developed by the latest technological tools and machinery. With the collaboration of the trained and highly skilled workers, the production process is being carried out. For further quality checks to avoid last stage delays in the delivery of the pipes many tests are performed. The tests that are performed by the quality checkers are-

Inspections -

to avoid the false results about the quality, controllers conduct different inspections. These inspections are of mostly of two types such as third-party inspection and the visual inspections. They are conducted by the third-party inspection squad who are the world’s reputed personnel, having good knowledge about the manufacturing of pipes.

Documents -

various documents are attached as proof of the good quality of products that are delivered to the clients. Some of the documents are-

Packaging of the pipes-

The Carbon Steel Lsaw Pipe is packed as to protect it from the extreme weather conditions. So, they are packed in the wooden boxes, crates, and pallets so that the pipes don’t get rust at the time of shipment. The shipment documents along with the product details are marked on the wooden boxes.